Certificates & Quality Policy

As A Plus Plastic, our main principle is to provide services and products of quality that will ensure the continuity of customer satisfaction.

With the awareness of legal and customer conditions, on this path;

- To meet customer expectations at the highest level without compromising quality in the industry

- To comply with quality management conditions

- To document and continuously improve in a way that meets the requirements of quality management standards,

- To ensure the continuity of standard requirements by constantly improving and developing our quality management system in compliance with official and legal requirements

- To closely follow technological developments in production and thus improve product quality are our main goals and policies.

As A Plus Plastic, we maintain a close relationship with all stakeholders within the framework of our ethical values and behavior rules. Thanks to an effective supplier development program, we ensure that we consistently receive high-level service and product. We believe that timely and accurate delivery of quality products can be achieved through effective communication and appropriate planning methodology both internally and externally. We benefit from an R&D center and facilities equipped with the most advanced technology to meet technological developments and new customer demands at the highest level. We apply our “0 Tolerance” health and safety initiative, which is shaped by rules and procedures that assist in keeping our employees, visitors, and community safe. We organize Management Review meetings on an annual basis to evaluate the effectiveness of our Quality Management System and revise if necessary.

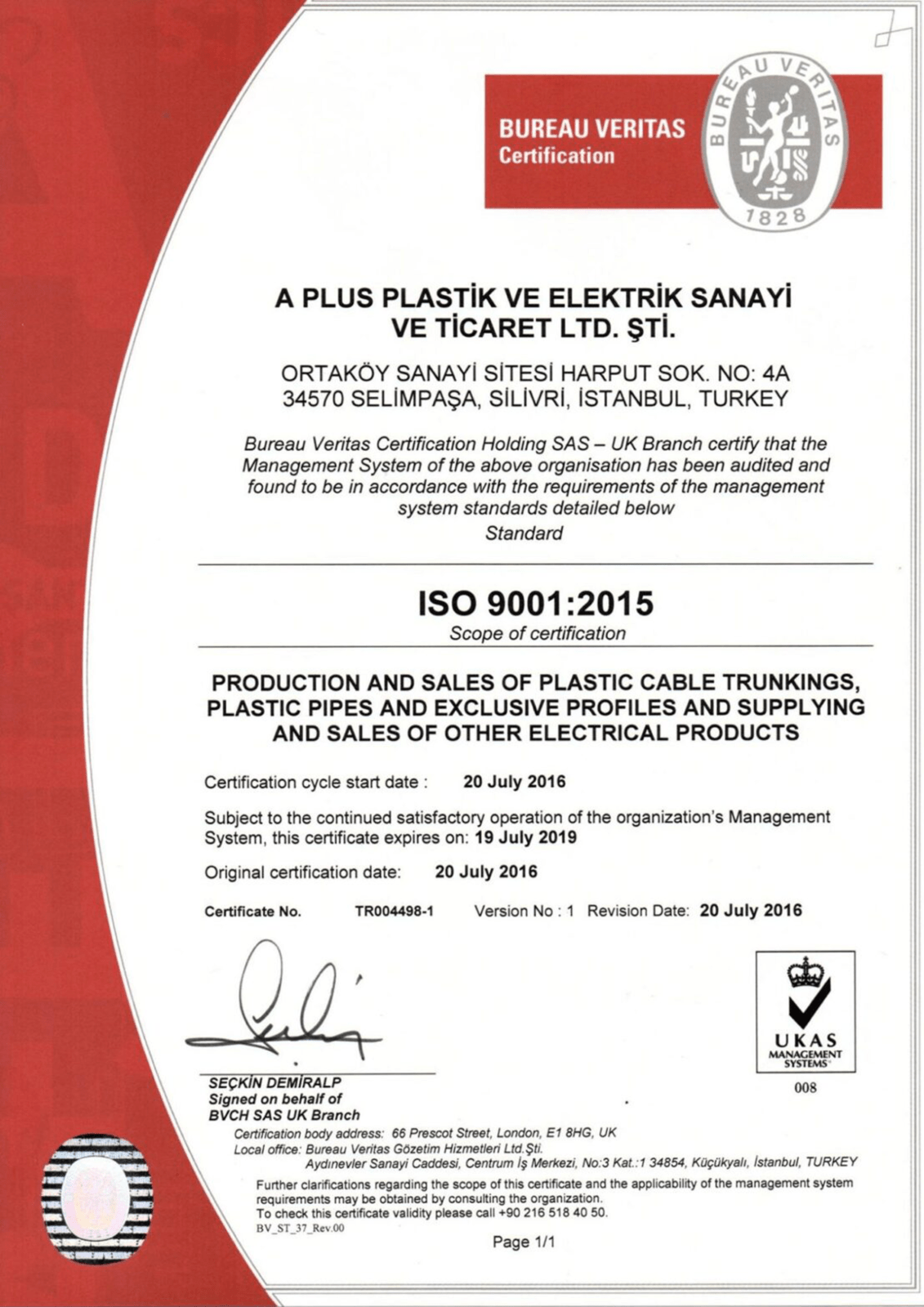

A Plus Electric has TSE (Turkish Standards Institute) and ISO 9001:2015 certificates.

Europen Norms

A Plus Electric has Europen norms.

ISO 9001:2015

This is an international standard that sets out the criteria for a quality management system. It is based on a number of quality management principles including a strong customer focus, the involvement of top management, a process approach, and continual improvement.

EN 50085-2-1

This is a European standard that specifies requirements for the installation and use of cable trunking systems and cable ducting systems intended for the accommodation, and where necessary for the electrically protective separation, of insulated conductors, cables and cords, and/or other electrical equipment in electrical and/or information & communication technology installations.

EN 50085-2-3

This is a part of the EN 50085 standard series, specifying requirements for cable trunking systems and cable ducting systems intended for installation on walls and ceilings.

EN 60670-1

This is a European standard that specifies the requirements for boxes, enclosures and combinations thereof, intended for the installation of electrical accessories with a rated voltage not exceeding 1 000 V a.c. and 1 500 V d.c.

EN 60670-24

This part of the EN 60670 series specifies requirements for enclosures and parts of them such as covers and frames intended for use with electrical accessories with a rated voltage not exceeding 1 000 V a.c. or 1 500 V d.c.

EN 61386-21

This is a European standard that specifies requirements for conduit systems buried underground including conduits and conduit fittings for the protection and management of insulated conductors and/or cables in electrical installations or in communication systems.

EN 61386-22

This standard specifies the requirements for conduit systems intended for installation on walls or ceilings, including conduits and conduit fittings for the protection and management of insulated conductors and/or cables in electrical installations or in communication systems.

EN 61386-24

This is a European standard that specifies the requirements for conduit systems intended for the protection and routing of insulated conductors and/or cables in electrical installations of buildings.

EN 61386-1

This is the general standard for conduit systems for cable management. It specifies requirements for conduit systems, including conduits and conduit fittings, for the protection and management of insulated conductors and/or cables in electrical installations or in communication systems.

Lab Tests

The products that manufactured for the first time in our company go through these tests

Flame Resistance Test

The CTS / CDS sample is subjected to the flame, non-ignition of the sample is observed or in the case of the ignition, the ignition source is removed and the duration of onset is measured.

Heat Resistance Test

Force is applied to the surface of the sample which is placed on the heated support by a steel ball. The deformation on the sample is observed. The resistance of the material to the heat is determined.

Glow Wire Test

The wire which is heated and glowed with excessive electrical charges is contacted with the sample surface for a certain period of time. The resistance of the material to heat and glow is determined.

Rutin Tests

The rutin test are applied to the conditioned sample of the first product that comes out from the machine. These tests are performed according to the specified test instructions.

Impact Resistance Test

The deformation of the conditioned sample caused by free-falling hammer from a certain height is observed. The resistance of the material to impact is determined.

Cable Support Test

The cable duct (cross sectional area>500mm2) mounted on a support is tested according to TS EN 50085-2-1 standard and the suitability of duct covers is observed.

High Voltage Test

Voltage is applied by the high voltage transformation to the aged sample by applying a humidification process for a certain period of time. The resistance of the material to electrical stress is determined.

Insulation Resistance Test

A direct current voltage is applied by the electrodes to the sample aged by humidifying. The insulation resistance of the material to electrical stress is determined.